CNC Turning is usually a cornerstone of contemporary manufacturing, featuring unparalleled precision, efficiency, and flexibility. This method is important for producing high-top quality cylindrical components across numerous industries, from automotive and aerospace to health care devices and consumer electronics. If

Parts with intricate patterns or limited tolerances demand slower machining speeds, that may enhance production time and price. As an example, a relatively basic turned component may well cost while in the double digits, while a lot more complex parts could possibly Expense in the hundreds.

Other uncategorized cookies are those who are increasingly being analyzed and also have not been categorised into a classification as nevertheless. Preserve & Acknowledge

In case you are a novice or are merely trying to find a smaller lathe with CNC programming abilities then this machine might just be best for your needs.

The chuck grips the machined component by its jaws. It attaches directly to the spindle but is replaceable, so distinct-sized parts might be machined.

For making matters even a lot easier, this machine is provided with a visual part programming system for proving out systems very easily and efficiently.

Tooling: The categories of tools expected for a specific task might also have an effect on the expense. Some Work may well require personalized or specialized tools, rising the expense.

It is possible to offset the length and angle of each and every tool and report it below Tools inside your Set up. The program will automatically pause the lathe’s movement and spindle allowing you to alter out your tool, or enabling the optional ATC Turret to rapidly transform to its following tool and carry on machining.

This can be also a fairly easy-to-use machine, which can be run by 220v single period and helps you to choose the voltage that best suits your preferences. The various voltage options and built-in electronic readout make this CNC lathe specially like minded to garages, universities, and modest fabricators.

ABS Plastic: ABS is really a hardy, impression-resistant plastic that machines well, making it a fantastic option for strong parts and prototypes.

The specialized storage or accessibility that is definitely used exclusively for statistical reasons. The complex storage or entry that is utilized exclusively for anonymous statistical reasons.

In contrast, CNC milling requires a workpiece secured to the movable desk. In cases like this, the cutting tool rotates and moves in to the steel piece, get more info eradicating product and creating a flat area.

The expression turning refers to manufacturing parts by cutting functions on the exterior floor. The alternative of turning is tedious, whereby lathe machines are utilized for making hollow parts, as an example.

five. Floor Finish: The desired surface finish can influence machining. Tough finishes are quicker and more cost-effective, though high-high-quality finishes could call for additional techniques and charges. You could learn more about some of the most well known surface ending options.

Gia Lopez Then & Now!

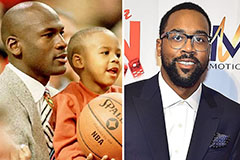

Gia Lopez Then & Now! Marcus Jordan Then & Now!

Marcus Jordan Then & Now! Robbie Rist Then & Now!

Robbie Rist Then & Now! Daryl Hannah Then & Now!

Daryl Hannah Then & Now! Mary Beth McDonough Then & Now!

Mary Beth McDonough Then & Now!